materials handled

We understand that all food & beverage materials have unique properties that help determine their quality and capacity for varied applications. We design and manufacture sanitary equipment that complies with strict agricultural associations and government agencies requirements. We know that safety, ingredient accuracy, cleanliness, dust containment, and limiting all types of cross-contamination are important to your business.

Materials

The Nol-tec advantage

We go beyond immediate project needs to understand your business, products, and stakeholders. We share your commitment to product performance, sustainable practices, and innovative solutions. We understand that transparency in the food & beverage industry is more important than ever with consumers demanding sustainability, clean labels, and organic food. We have the technical expertise, industry experience, and proven technology to help your company produce superior food and beverages to nourish the world for generations to come.

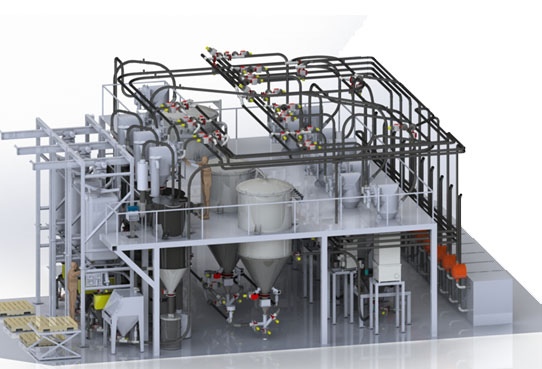

Global Seafood Processor Upgrades Legacy System

One of the largest wild-caught, sustainable seafood processors in the world was committed to modernizing the equipment in its manufacturing facility. Since the 1980s, the processor has been producing Surimi, a frozen fish protein manufactured from Pollock and commonly used as the main ingredient in many imitation crab products. The Surimi production process at the facility consists of an upstairs powder room where a sugar, sorbitol, and preservative recipe is blended and then transported via a powder handling system to the lower level fish processing floor.

View Case Study

How can we help?

Maybe you need a new system, an upgrade to an existing system, or a retrofit. Regardless of size, industry, or material, we are here to help you get your project and product moving.

Get in touch