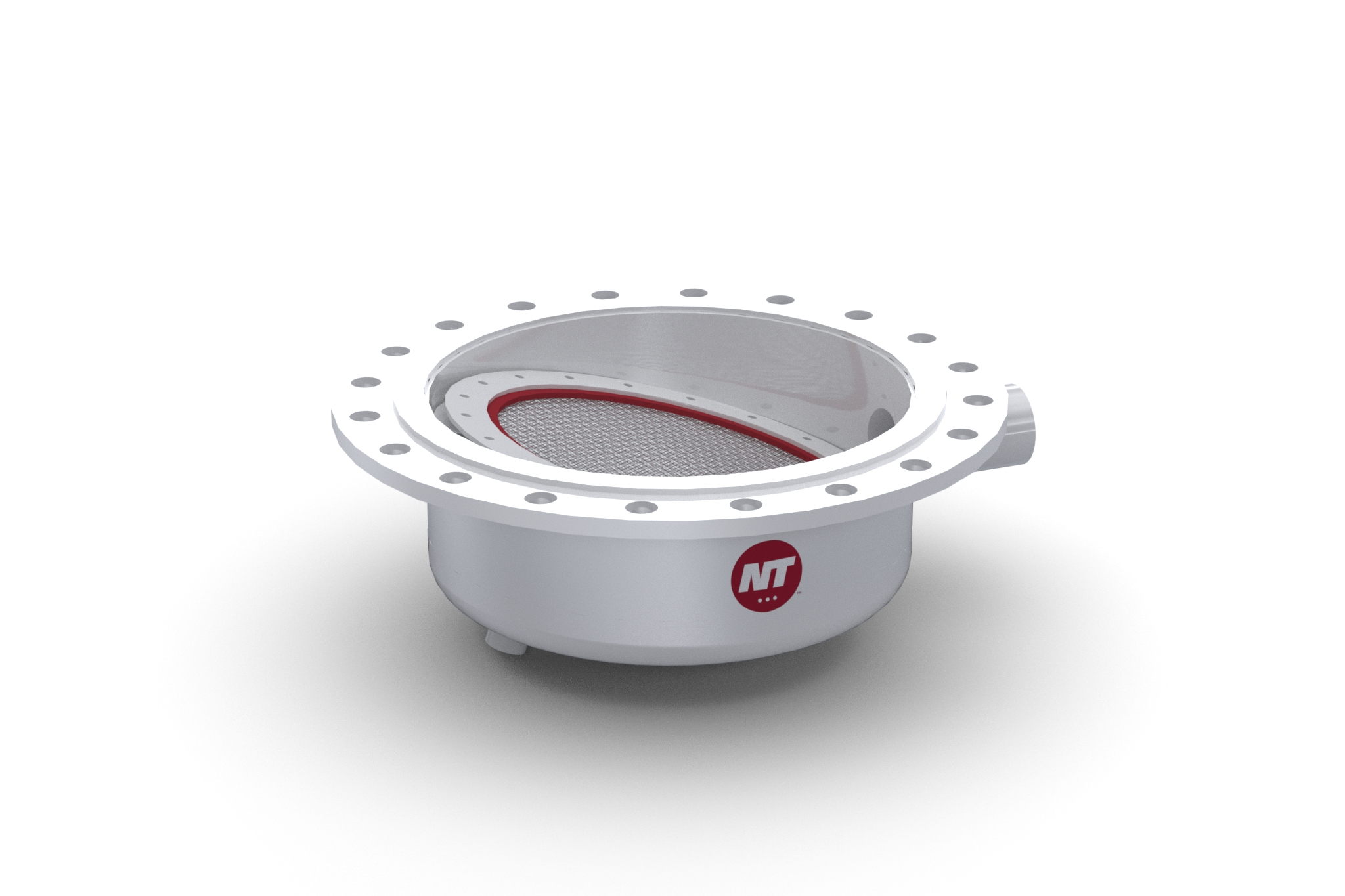

Air Pad Discharger

Nol-Tec air pad dischargers improve material flow from vessels to conveying lines. Two models are available depending on the type of material being handled.

Specifications

To learn more about our Air Pad Discharger, please review the specifications below. If you have additional questions, please feel free to hit the get in touch button below and someone from our team will follow-up promptly.

Standard Features:

- Heavy-duty design

- Flanged for grooved end pipe coupling mounting to vessel

- Single chamber bottom of fiber material (Model 391-G)

- Discharge pipe to aeration sidewall membrane (Model 391-M)

- 16-bolt flange-mounted air chamber

- One-inch air connections

- Pre-assembled air and electrical controls

OPTIONAL FEATURES:

- Stainless steel construction

- Stainless steel product contact surfaces

- 316SS aeration membrane

- High-temperature (HT) design: 350° F maximum

- Air Assist™ convey line air management system

- Dual Chamber bottom and aerated sidewall of 304SS membrane (Model 391-M)

- Side fluidization

- Electrical: 110-120V; 50-60Hz

SPECIFICATIONS:

- Compressed air: Clean and dry at 80 PSIG minimum

- Electrical: 24VDC

- Temperature range: -200 F to +2000 F

- Weight: 200 lbs

Resources

We have a vast knowledge base of research and hands-on experience that covers topics from market trends to complex dry bulk material handling challenges.

Product Literature

How can we help?

Maybe you need a new system, an upgrade to an existing system, or a retrofit. Regardless of size, industry, or material, we are here to help you get your project and product moving.

Get in touch