How to unload 3M™ Glass Bubbles using a Nol-Tec bulk bag unloading method

We are at the Nol-Tec test lab facility in Lino Lakes, Minnesota to show you how to unload 3M™ Glass Bubbles using a bulk bag unloading method. Our method features Nol-Tec’s bulk bag unloaders and exclusive aeration lance designed specifically for handling 3M™ Glass Bubbles.

Watch Now

Global Seafood Processor Upgrades Legacy System

One of the largest wild-caught, sustainable seafood processors in the world was committed to modernizing the equipment in its manufacturing facility. Since the 1980s, the processor has been producing Surimi, a frozen fish protein manufactured from Pollock and commonly used as the main ingredient in many imitation crab products. The Surimi production process at the facility consists of an upstairs powder room where a sugar, sorbitol, and preservative recipe is blended and then transported via a powder handling system to the lower level fish processing floor.

View case study

rubber compound producer

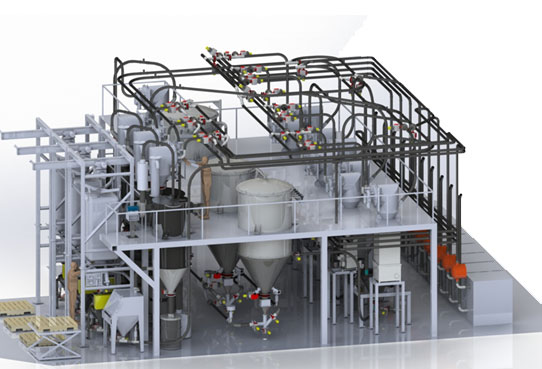

Lauren International is dynamic provider of superior products, services, and solutions across a diverse spectrum of markets through their many subsidiary companies. Demand for Lauren International’s molded and extruded rubber products began to rise. Consequently, the need for rubber compounds increased and so did the cost. To meet market demand, improve the rubber compound’s quality, and reduce costs, Lauren International decided to build their own rubber compound manufacturing facility.

View Case Study

What Can We Do For You?

Contact us to speak with a member of our sales team about a specific system or our capabilities.

Get in touch